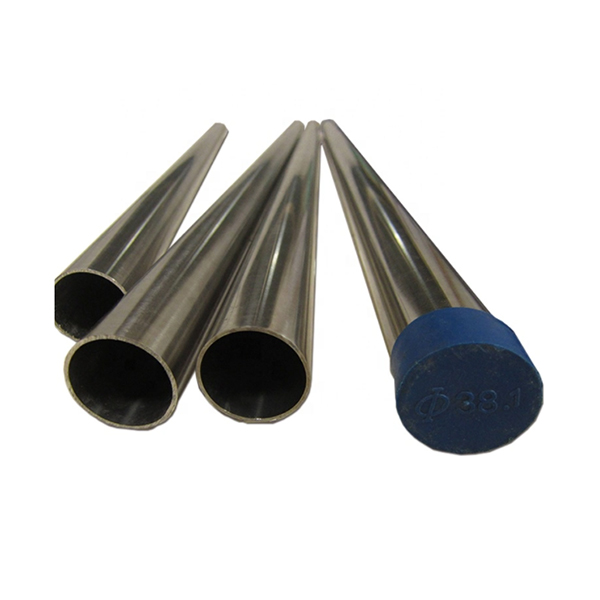

Hot Rolled enweghị nkebi ígwè tube

Igwe anaghị agba nchara na-ekpo ọkụ na-ekpo ọkụ, ntụgharị na-ekpo ọkụ na-emetụta ntụgharị oyi, ntụgharị oyi na-atụgharị n'okpuru okpomọkụ recrystallization, na ntụgharị ọkụ na-agbagharị n'elu okpomọkụ recrystallization.

Igwe anaghị agba nchara na-ekpo ọkụ Rolled, Uru

Ọ nwere ike ibibi usoro nkedo nke ígwè ingot, nụchaa nha ọka nke ígwè, ma wepụ ntụpọ nke microstructure, nke mere na a na-ejikọta ígwè ahụ ma na-emeziwanye ihe ndị na-emepụta ihe.Ọganihu a na-egosipụtakarị na ntụgharị ntụgharị, nke mere na nchara adịghịzi isotropic ruo n'ókè ụfọdụ.Afụ, mgbawa na ntọhapụ emere n'oge nkedo nwekwara ike welded n'okpuru oke okpomọkụ na nrụgide.

Nhazi

Hot Rolled Seamless Steel tube, Ọ na-ekewa n'ime izugbe ígwè ọkpọkọ, ala na-ajụ mgbali ji esi mmiri ọkụ ọkpọkọ, elu mgbali ji esi mmiri ọkụ ọkpọkọ, alloy ígwè ọkpọkọ, igwe anaghị agba nchara ọkpọkọ, mmanụ ụgbọala cracking ọkpọkọ, geological ígwè ọkpọkọ na ndị ọzọ ígwè ọkpọkọ.

Oyi akpọrepu (pịa) enweghị nkebi ọkpọkọ na mgbakwunye na izugbe ígwè ọkpọkọ, ala na-ajụ mgbali ji esi mmiri ọkụ ọkpọkọ, elu mgbali ji esi mmiri ọkụ ígwè ọkpọkọ, alloy ígwè ọkpọkọ, igwe anaghị agba nchara, mmanụ ụgbọala cracking ọkpọkọ, ndị ọzọ ígwè ọkpọkọ, tinyekwara carbon thin- ọkpọkọ nchara, alloy mkpa-mgbidi ígwè ọkpọkọ, igwe anaghị agba nchara, ọkpọkọ nchara pụrụ iche.The elu dayameta nke na-ekpo ọkụ akpọrepu enweghị enweghị nkebi pipe bụ n'ozuzu karịa 32mm na mgbidi ọkpụrụkpụ bụ 2.5-75mm.The elu dayameta nke oyi akpọrepu enweghị nkebi ígwè ọkpọkọ nwere ike iru 6mm na mgbidi ọkpụrụkpụ nwere ike iru 0.25mm.The elu dayameta nke mkpa-walled ọkpọkọ nwere ike iru 5mm na mgbidi ọkpụrụkpụ bụ ihe na-erughị 0.25mm.

General enweghị nkebi ígwè anwụrụ: ọ bụ nke 10, 20, 30, 35, 45 na ndị ọzọ elu-edu carbon bonded ígwè 16Mn, 5MnV na ndị ọzọ ala alloy bughi ígwè ma ọ bụ 40Cr, 30CrMnSi, 45Mn2, 40MnB na ndị ọzọ alloy ígwè akpọrepu. oyi akpọrepu.10, 20 na ndị ọzọ dị ala carbon ígwè n'ichepụta enweghị nkebi pipeline bụ tumadi ji maka mmiri pipeline.45, 40Cr na ndị ọzọ na-ajụ carbon ígwè mere nke enweghị nkebi ọkpọkọ rụpụta n'ibu akụkụ, dị ka ụgbọ ala, traktọ mesiri ike akụkụ.N'ozuzu ojiji nke enweghị nkebi ígwè ọkpọkọ iji hụ na ike na flattening ule.A na-ebunye ọkpọkọ ígwè na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ ma ọ bụ ọnọdụ okpomọkụ.Nnyefe oyi na-atụ bụ okpomọkụ - ọgwụgwọ.

A na-anabata ndịiche nke dayameta mpụta emeziri nke ọma

D1 ± 1.5%, kacha nta ± 0.75mm

D2 gbakwunyere ma ọ bụ mwepu 1.0%.Opekempe +/- 0.50 mm

D3 +/- 0.75%.Opekempe +/- 0.30 mm

D4 +/- 0.50%.Opekempe +/- 0.10 mm

Steel tube arọ ngụkọta oge usoro

[( dayameta dị n'èzí - ọkpụrụkpụ mgbidi) * ọkpụrụkpụ mgbidi] x0.02466 = kg / m (arọ kwa mita)

Igwe anaghị agba nchara na-ekpo ọkụ na-ekpo ọkụ, ebumnuche na-arụ ọrụ

1. Ụdị ihe owuwu bụ: n'okpuru ụgbọ njem pipeline bụ ihe ndị ọzọ, mmepụta ụlọ nke mmiri dị n'ime ala, ụgbọ mmiri ọkụ ọkụ.

2. Mechanical nhazi, ebu aka uwe, nhazi ngwa ngwa igwe, wdg.

3. Eletriki: nnyefe gas, mmiri na-emepụta mmiri mmiri mmiri.

4. Igwe ọkụ ikuku na-egbochi ọkpọkọ, wdg.

Nkọwapụta

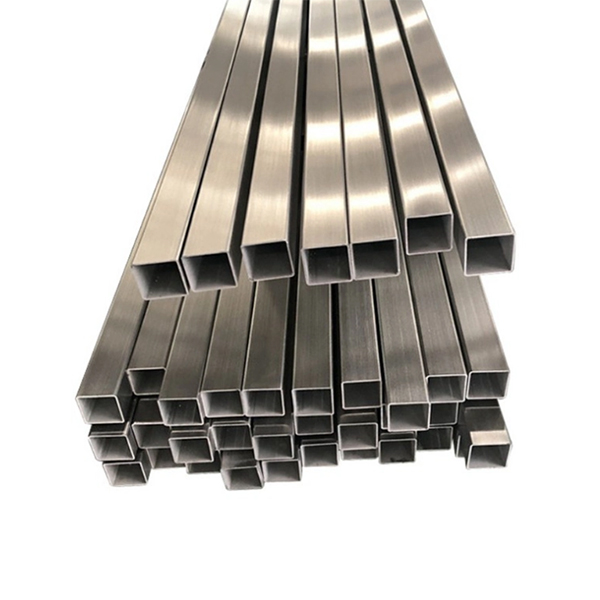

| Aha ngwaahịa | Igwe anaghị agba nchara / tube |

| Ọkọlọtọ | ASME, ASTM, EN, BS, GB, DIN, JIS wdg |

| Ụdị | 201/202/304/304L/316/316L/ 321/309S/310S/410/420/430 |

| Asambodo | BV, ISO, CE, SGS wdg |

| Ụdị | Enweghị enweghị ntụpọ & welded |

| Dayameta dị n'èzí (OD) | 3-1220 mm |

| Ọkpụrụkpụ | 0.5-50mm |

| Ogologo | 6000mm 5800mm 12000mm ma ọ bụ ahaziri |

| Usoro | Oyi adọtara ma ọ bụ na-ekpo ọkụ |

| Elu | 2B, No.1, No.4, HL, BA, 8K wdg |

| Ngwa | Industrylọ ọrụ, kemịkalụ, ọkụ eletrik, igwe, ihe owuwu, ihe ndozi, wdg. |

| Nkwakọ ngwaahịa | Ọkọlọtọ mbupụ oke osimiri kwesịrị mbukota |

| Oge Mbuga ozi | Ụbọchị 7-15 na-arụ ọrụ mgbe nkwụnye ego gasịrị |

| Usoro ahia | FOB, CFR, CIF, EXW |

| Usoro ịkwụ ụgwọ | 30%T/T,L/C |

Ọgwụgwọ elu

| Elu | Nkọwa | Ngwa |

| Mba.1 | N'elu okokụre site okpomọkụ ọgwụgwọ na pickling ma ọ bụ Filiks kwekọrọ n'ebe ahụ mgbe na-ekpo ọkụ Rolling. | Tankị kemịkalụ, ọkpọkọ wdg. |

| Nke 3 | Ndị mechara site na polishing na No.100 ka No.120 abrasives kpọmkwem na JIS R6001. | Ngwa kichin, Ihe owuwu ụlọ wdg. |

| Nọmba.4 | Ndị mechara site na polishing na No.150 ka No.180 abrasives kpọmkwem na JIS R6001. | Ngwa kichin, Owuwu ụlọ, akụrụngwa ọgwụ wdg. |

| 2B | Ndị ahụ emechara, ka oyi gachara, site na ọgwụgwọ okpomọkụ, ịhịa aka n'ahụ ma ọ bụ ọgwụgwọ ndị ọzọ dabara na nke ikpeazụ site n'ịtụgharị oyi na-enye ọkụ kwesịrị ekwesị. | Akụrụngwa ọgwụ, ụlọ ọrụ nri, ihe eji ewu ụlọ, arịa kichin wdg. |

| BA (No.6) | Ndị na-edozi ya na ọgwụgwọ okpomọkụ na-egbuke egbuke mgbe oyi na-atụgharị. | Ngwa kichin, Akụrụngwa eletriki, Owuwu ụlọ wdg. |

| Igwefoto (No.8) | Na-enwu dị ka enyo | Ihe owuwu ụlọ, ịchọ mma wdg. |

| Ntutu isi | Ndị na-emecha polishing ka ọ na-enye na-aga n'ihu polishing streaks site na iji abrasive nke kwesịrị ekwesị ọka size. | Ihe owuwu ụlọ wdg. |

Ngwakọta kemịkalụ

| Ọkwa | C | Si | Mn | P | S | Ni | Cr | Mo | |||||

| 201 | ≤0.15 | ≤0.75 | 5. 5-7.5 | ≤0.06 | ≤ 0.03 | 3.5-5.5 | 16.0 -18.0 | - | |||||

| 202 | ≤0.15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - | |||||

| 301 | ≤0.15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - | |||||

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - | |||||

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - | |||||

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - | |||||

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - | |||||

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | ||||||

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0- | |||||

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 - | |||||

| 321 | ≤ 0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 17.0 -1 9.0 | - | |||||

| 630 | ≤ 0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - | |||||

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - | |||||

| 904L | ≤ 2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0 · 28.0 | 19.0-23.0 | 4.0-5.0 | |||||

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | |||||

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |||||

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19-0.22 | 0.24-0 .26 | - | |||||

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - | |||||

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | 0.040 | ≤ 0.03 | ≤0.60 | 16.0-18.0 | - | |||||

| Ngwaahịa Aha | Ihe onwunwe | Ọkọlọtọ | Nha (mm) | Ngwa | |||||||||

| Obere okpomọkụ tube | 16MnDG 10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 | GB/T18984- 2003 ASTM A333 | OD: 25mm ~ 508mm WT: 3mm ~ 100mm | Tinye na -45ºC ~ 195ºC obere okpomọkụ ụgbọ mmiri na obere okpomọkụ mgbanwe ọkpọkọ. | |||||||||

| Igwe mmiri ọkụ dị elu | 20G ASTMA106B ASTMA210A ST45.8-III | GB5310-1995 ASTM SA106 ASTM SA210 DIN17175-79 | OD: 8-1240* WT: 1-200 | Kwesịrị ekwesị maka imepụta tube na-ekpo ọkụ ọkụ, nkụnye eji isi mee, ọkpọkọ uzuoku, wdg | |||||||||

| Mmanụ na-agbawa tube | 10 20 | GB9948-2006 | OD: 8-630* WT:1-60 | Ejiri ya na tube ọkụ refinery mmanụ, ọkpọkọ mgbanwe okpomọkụ | |||||||||

| Obere igwe ọkụ ọkụ tube | 10 # 20# 16 nde, Q345 | GB3087-2008 | OD: 8-1240* WT: 1-200 | Kwesịrị ekwesị maka imepụta usoro dị iche iche nke igwe ọkụ ọkụ dị ala na nke ọkara yana igwe ọkụ locomotive | |||||||||

| Nhazi izugbe nke tube | 10#,20#,45#,27SiMn ASTM A53A, B 16 nde, Q345 | GB/T8162- 2008 GB/T17396- 1998 ASTM A53 | OD: 8-1240* WT: 1-200 | Tinye na nhazi n'ozuzu, nkwado injinia, nhazi igwe, wdg | |||||||||

| Ihe mkpuchi mmanụ | J55,K55,N80,L80 C90,C95,P110 | API SPEC 5CT ISO 11960 | OD: 60-508* WT: 4.24-16.13 | A na-eji maka mmịpụta mmanụ ma ọ bụ gas na mmanụ Wells casing, nke a na-eji mmanụ na gas dị n'akụkụ akụkụ | |||||||||

Ngosipụta ngwaahịa