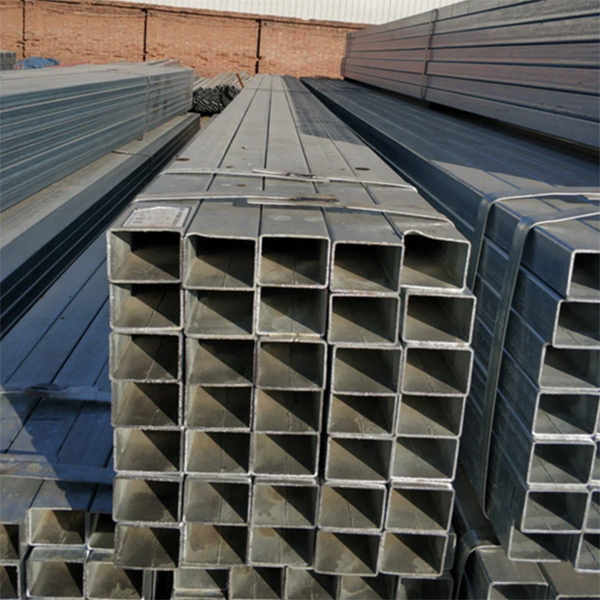

Ọkpụkpụ Steel Structural Square

Square structural ígwè tubing, makwaara dị ka welded anwụrụ, ka nke ígwè efere ma ọ bụ warara mgbe crimping akpụ welded square ọkpọkọ.

Square structural ígwè tubing, ihe ndị a na-ejikarị bụ: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 018Cr19, 10Cr,Nicr19 na 10Cr19Ni

Welded igwe anaghị agba nchara anwụrụ maka ịchọ mma (GB/T 18705-2002), welded igwe anaghị agba nchara anwụrụ maka ụlọ mma (JG/T 3030-1995), welded ígwè ọkpọkọ maka ala-nrụgide mmiri njem (GB/T 3091-2001), na welded ígwè ọkpọkọ maka okpomọkụ Exchanger (YB4103-2000).

Usoro mmepụta

Square structural tubing ígwè, warara oghere nwere ike iji na-emepụta welded ọkpọkọ na ibu dayameta, na oghere nke otu obosara nwere ike iji na-emepụta welded ọkpọkọ na dị iche iche dayameta.Ma tụnyere na otu ogologo ogologo onuete square ọkpọkọ, weld ogologo na-abawanye site 30 ~ 100%, na mmepụta ọsọ bụ ala.

Nnukwu ma ọ bụ oké na dayameta square structural ígwè tubing, N'ozuzu mere nke ígwè billet ozugbo, na obere welded anwụrụ mkpa mgbidi welded ọkpọkọ naanị kwesịrị ka ozugbo welded site nchara eriri.Mgbe polishing dị mfe, waya dị njikere.Ya mere, obere dayameta welded ọkpọkọ na-ejikarị na-eji ogologo ịgbado ọkụ, nnukwu dayameta welded ọkpọkọ na-ejikarị gburugburu ịgbado ọkụ.

Chebe The Performance

square structural ígwè tubing, Ọ bụ aha maka square ọkpọkọ, nke bụ ọkpọkọ na otu ogologo na abụọ.A na-eme ya nke mpempe akwụkwọ site na ngwọta usoro na ntụgharị.Nọmalị, warara bụ unpacked, ewepụghị, crimped, welded n'ime a gburugburu tube, na mgbe ahụ akpọrepu site gburugburu tube Q215 welded square tube wee bee n'ime ogologo nke ina.Nọmba nkịtị bụ 50 kwa mkpọ.Ike na-ezo aka na ọrụ nke iguzogide mmebi (ezigbo nrụrụ plastik ma ọ bụ mgbaji) nke Q215 welded square pipe data n'okpuru ibu static.N'ihi na ibu nke ụdị nkwụsịtụ, nkwụsịtụ, winding, shear na ụzọ ndị ọzọ, n'ihi na ike na-ekewa n'ime ike ike, ike mkpakọ, na-ehulata ike, ịkwa akwa na ihe ndị ọzọ.Ụdị ike niile na-enwekarị kọntaktị doro anya, iji ike tensile eme ihe dị ka agịga ike kachasị mkpa.A na-akpọ ike iguzogide mbibi a na-akpọ ike ụgwọ.

A na-akpọ ibu dị n'akụkụ akụkụ ndị nwere ọganihu dị ukwuu nke a na-akpọ ụgwọ nhazi ụgwọ.The ike, plasticity na Angle tụlere n'azụ square anwụrụ ụgwọ n'usoro siri ike n'okpuru edinam nke metal ụgwọ n'usoro ibu bụ niile igwe ọrụ gauges n'okpuru edinam static ibu nke Q215 welded square ọkpọkọ.Na omume, ọtụtụ igwe na-n'okpuru ugboro ugboro ibu ọrụ, n'okpuru ebe a ohere dum ike ọgwụgwụ.Akụkụ ike ọgwụgwụ bụ ịtụ data igwe dị nro na ọkwa siri ike nke agịga.The kasị ụkọ usoro nke esịtidem Angle fixing na ndụ ugbu a bụ nrụgide Angle usoro, nke bụ iji a ụfọdụ ọnụ ọgụgụ nke ihe udi nke nrụgide isi n'okpuru a ụfọdụ ibu na-enwe n'ime ule Q215 welded square tube data elu, dị ka. na nrụgide n'ime ọkwa iji chọpụta uru akụkụ.Ụzọ ole na ole a na-eji bụ HB, HRA, HRB, HRC na HV.Angular plasticity na-ezo aka ike nke data metal n'okpuru ibu, plastic deformation (na-adịgide adịgide deformation) na-enweghị mmebi.Plastic Q215 welded square tube na-abụghị ọkọlọtọ enweghị nkebi square tube bụ enweghị nkebi gburugburu tube extrusion ịkpụzi.The enweghị nkebi tube na weld ihe pụtara, ọ bụ a square isi tube ụdị (torque tube), mmụọ nke ọtụtụ di iche iche nke ihe na-enwe ike mebere a party ọkpọkọ (square torque tube), ọ bụ ọkara si, gịnị mere, ihe ojiji. bụ Central, nnukwu nta Q215 welded square tube ígwè tube dị ka a nta, n'ihi na square tube Ọdịdị, whitewash square tube, architects anwụrụ (square torque tube), wdg Square tube Okwu Mmalite Square tube ọrụ.

Ngwakọta kemịkalụ

S460N ihe

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kacha 0.2 | kacha 0.6 | 1-1.7 | kacha 0.8 | kacha 0.03 | Ọnụahịa kasị elu nke 0.025 | kacha 0.3 | kacha 0.1 | kacha 0.2 | Ọnụahịa kasị elu nke 0.025 | kacha 0.05 | kacha 0.05 | kacha 0.02 | kacha elu 0.55 | kacha elu 0.55 |

S420N ihe

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kacha 0.2 | kacha 0.6 | 1-1.7 | kacha 0.8 | kacha 0.03 | Ọnụahịa kasị elu nke 0.025 | kacha 0.3 | kacha 0.1 | kacha 0.2 | Ọnụahịa kasị elu nke 0.025 | kacha 0.05 | kacha 0.05 | kacha 0.02 | kacha elu 0.55 | kacha elu 0.52 |

Ihe S420NL:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kacha 0.2 | kacha 0.6 | 1-1.7 | kacha 0.8 | Ọnụahịa kasị elu nke 0.025 | kacha 0.02 | kacha 0.3 | kacha 0.1 | kacha 0.2 | Ọnụahịa kasị elu nke 0.025 | kacha 0.05 | kacha 0.05 | kacha 0.02 | kacha elu 0.55 | kacha elu 0.52 |

Ihe S460NL:

| C | Si | Mn | Ni | P | S | Cr | Mo | V | N | Nb | Ti | Al | Cu | CEV |

| kacha 0.2 | kacha 0.6 | 1-1.7 | kacha 0.8 | Ọnụahịa kasị elu nke 0.025 | kacha 0.02 | kacha 0.3 | kacha 0.1 | kacha 0.2 | Ọnụahịa kasị elu nke 0.025 | kacha 0.05 | kacha 0.05 | kacha 0.02 | kacha elu 0.55 | kacha elu 0.55 |

Ihe eji arụ ọrụ

S460N ihe

| Ọkpụrụkpụ aha (mm): | ruo 100 | 100-200 |

| Rm- Ike tensile (MPa) | 540-720 | 530-710 |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 |

| ReH- ike mkpụrụ kacha nta (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Mmetụta ike (J) longitud., (+N) | +20° 55 | 0° 47 | -10° 43 | -20° 40 | |

| KV- Mmetụta ike (J) transverse, (+N) | +20° 31 | 0° 27 | -10° 24 | -20° 20 | |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-200 |

| A- Min.elongation Lo = 5,65 √ Ya mere (%) | 17 | 17 | 17 | 17 | 17 |

Ihe S420N:

| Ọkpụrụkpụ aha (mm): | ruo 100 | 100-200 | 200-250 |

| Rm- Ike tensile (MPa) | 520-680 | 500-650 | 500-650 |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 | 200-250 |

| ReH- ike mkpụrụ kacha nta (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Mmetụta ike (J) longitud., (+N) | +20° 55 | 0° 47 | -10° 43 | -20° 40 | |

| KV- Mmetụta ike (J) transverse, (+N) | +20° 31 | 0° 27 | -10° 24 | -20° 20 | |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-200 | 200-250 |

| A- Min.elongation Lo = 5,65 √ Ya mere (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Ihe S420NL:

| Ọkpụrụkpụ aha (mm): | ruo 100 | 100-200 | 200-250 |

| Rm- Ike tensile (MPa) | 520-680 | 500-650 | 500-650 |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 | 200-250 |

| ReH- ike mkpụrụ kacha nta (MPa) | 420 | 400 | 390 | 370 | 360 | 340 | 330 | 320 |

| KV- Mmetụta ike (J) longitud., (+N) | +20° 63 | 0° 55 | -10° 51 | -20° 47 | -30° 40 | -40° 31 | -50° 27 | |

| KV- Mmetụta ike (J) transverse, (+N) | +20° 40 | 0° 34 | -10° 30 | -20° 27 | -30° 23 | -40° 20 | -50° 16 | |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-200 | 200-250 |

| A- Min.elongation Lo = 5,65 √ Ya mere (%) | 19 | 19 | 19 | 18 | 18 | 18 |

Ihe S460NL:

| Ọkpụrụkpụ aha (mm): | ruo 100 | 100-200 |

| Rm- Ike tensile (MPa) | 540-720 | 530-710 |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-100 | 100-150 | 150-200 |

| ReH- ike mkpụrụ kacha nta (MPa) | 460 | 440 | 430 | 410 | 400 | 380 | 370 |

| KV- Mmetụta ike (J) longitud., (+N) | +20° 63 | 0° 55 | -10° 51 | -20° 47 | -30° 40 | -40° 31 | -50° 27 | |

| KV- Mmetụta ike (J) transverse, (+N) | +20° 40 | 0° 34 | -10° 30 | -20° 27 | -30° 23 | -40° 20 | -50° 16 | |

| Ọkpụrụkpụ aha (mm): | ruo 16 | 16-40 | 40-63 | 63-80 | 80-200 |

| A- Min.elongation Lo = 5,65 √ Ya mere (%) | 17 | 17 | 17 | 17 | 17 |

Ngosipụta ngwaahịa