TC2 Titanium Alloy Aheet Plate

TC2 Titanium Alloy Aheet Plate, Alloy dabeere na titanium na ihe ndị ọzọ agbakwunyere.E nwere ụdị abụọ nke kristal homogenous na titanium: α titanium nwere nnukwu hexagonal Ọdịdị dị n'okpuru 882 ℃, na β titanium nwere cube etiti ahụ dị n'elu 882 ℃.

Nka nka

1. Ngwakọta kemịkalụ nke titanium na titanium alloy plate ga-agbaso usoro GB / T 3620.

2. N'ihe banyere nlegharị anya, nkwụsị nke a na-ekwe ka ihe mejupụtara kemịkalụ ga-agbaso usoro GB/T 3620.

a.ndahie nke a na-ekwe ka ọkpụrụkpụ nke efere ahụ kwesịrị irubere usoro nke Tebụl 1.

b.nke ekwe omume nke obosara efere na ogologo kwesịrị isonyere ndokwa nke Tebụl 2.

c.a ga-egbutu akụkụ nke efere ahụ n'akụkụ aka nri dị ka o kwere mee.Ngbanwe ahụ ekwesịghị ịgafe ogologo na obosara nke mpempe akwụkwọ

TC2 Titanium Alloy Aheet Plate, Nkọwapụta Mmepụta

T 0.5-1.0mm × W1000mm × L 2000-3500mm

T 1.0-5.0mm × W1000-1500mm × L 2000-3500mm

T 5.0- 30mm × W1000-2500mm × L 3000-6000mm

T 30- 80mm × W1000mm × L 2000mm

TC2 Titanium Alloy Aheet Plate, Ọnọdụ mmepụta

Steeti arụ ọrụ na-ekpo ọkụ (R) Oyi na-arụ ọrụ (Y) Steeti na-ekpo ọkụ (M)

TC2 Titanium Alloy Aheet Plate, Reference Standard

1: GB 228 Metal tensile ule usoro

2: GB/T 3620.1 Titanium na titanium alloy akara ule na chemical mejupụtara

3: GB/T3620.2 Titanium na titanium alloy esichara ngwaahịa kemịkalụ mejupụtara na ihe mejupụtara ekwe ndiiche

4: GB 4698 Usoro oke mmiri maka nyocha kemịkalụ nke titanium, titanium na ferroalloys

TC2 Titanium Alloy Aheet Plate, chọrọ nka nka

1: Ngwakọta kemịkalụ nke titanium na titanium alloy efere ga-agbaso usoro GB / T 3620.1.N'ihe banyere nlegharị anya, ndahie nke ihe mejupụtara kemịkalụ ga-agbaso usoro GB/T 3620.2.

2: Ntughari nke ekwe omume nke ọkpụrụkpụ nke efere ahụ kwesịrị ịgbaso ndokwa nke Tebụl 1.

3: The allowable deviation nke efere obosara na ogologo kwesịrị isonyere ndokwa nke Tebụl 2.

4: A ga-egbutu akụkụ nke efere ahụ n'akụkụ aka nri dị ka o kwere mee.Ngbanwe ahụ ekwesịghị ịgafe ogologo na obosara nke mpempe akwụkwọ

Alloying

TC2 Titanium Alloy Aheet Plate, Alloy dabeere na titanium na ihe ndị ọzọ agbakwunyere.E nwere ụdị abụọ nke kristal homogenous na titanium: α titanium nwere nnukwu hexagonal Ọdịdị dị n'okpuru 882 ℃, na β titanium nwere cube etiti ahụ dị n'elu 882 ℃.

(1) Enwere ike kewaa ihe ndị na-eme ihe n'ụdị atọ dịka mmetụta ha na-enwe na okpomọkụ mgbanwe oge:

α - ihe kwụsiri ike, dị ka aluminom, carbon, oxygen na nitrogen, na-eme ka usoro α kwụsie ike ma na-abawanye okpomọkụ mgbanwe oge.Aluminom bụ ihe bụ isi alloying element nke titanium alloy, nke nwere mmetụta doro anya na imeziwanye ike nke alloy na ụlọ okpomọkụ na okpomọkụ dị elu, na-ebelata ike ndọda na ịba ụba modul.

(2) β-stable ọcha nwere ike kewaa ụzọ abụọ: isocrystalline na eutectoid.Ngwaahịa emere nke titanium alloy

Nke mbụ nwere molybdenum, niobium, vanadium na ndị ọzọ;Nke ikpeazụ nwere chromium, manganese, ọla kọpa, ígwè, silicon na ndị ọzọ.

(3) Ihe ndị na-enwe mmetụta dị nta na okpomọkụ mgbanwe oge bụ ihe na-anọpụ iche, dị ka zirconium na tin.

Oxygen, nitrogen, carbon na hydrogen bụ isi adịghị ọcha na alloys titanium.Solubility nke oxygen na nitrogen na akụkụ α ka ukwuu, nke nwere mmetụta na-ewusi ike na titanium alloy, ma na-ebelata plasticity.Ọdịnaya nke oxygen na nitrogen na titanium na-adịkarị n'okpuru 0.15 ~ 0.2% na 0.04 ~ 0.05%, n'otu n'otu.Hydrogen nwere ntakịrị solubility n'oge α, oke hydrogen gbazere na alloys titanium na-emepụta hydrides, nke na-eme ka alloy na-akụri.A na-achịkwa ọdịnaya hydrogen na alloy titanium n'okpuru 0.015%.Mgbasa nke hydrogen na titanium nwere ike ịtụgharị ma nwee ike iwepụ ya site na mwepu oghere.

Ngwakọta kemịkalụ

| Ọkwa | N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

Ike ọdụdọ

| Ọkwa | Mgbatị(%) | Ike tensile (Nkeji) | Ike Mpụta (Nkeji) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

Ngwaahịa Titanium na Alloy

| Aha ngwaahịa | Nkọwapụta |

| Titanium Rod & Bar & Ingots | Ф3mm ~ Ф1020mm, kacha arọ bụ ruo 12t |

| Titanium Slab | (80 ~ 400) mm × (~ 1500) mm × (~ 2600) mm |

| Titanium Forgings | Arọ kwa ibe≤2000kg |

| Titanium efere akpọrepu ọkụ | (4 ~ 100) mm × (800 ~ 2600) mm × (2000 ~ 12000) mm |

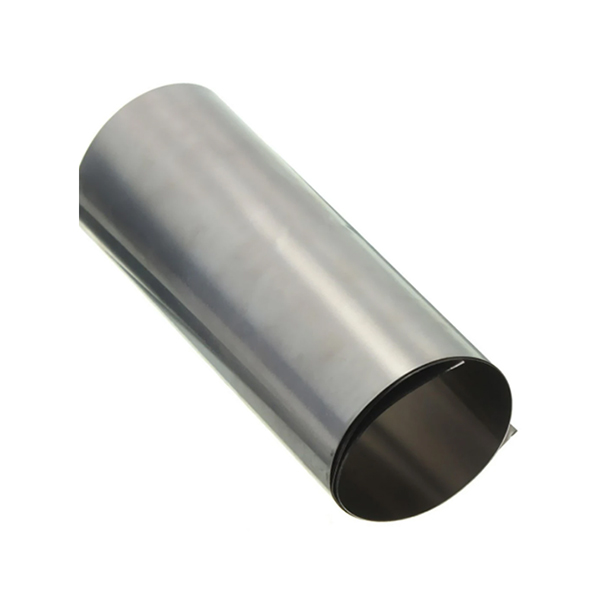

| Akwụkwọ mpịakọta Titanium oyi | (0.01 ~ 4.0) mm × (800 ~ 1560) mm × ( ~ 6000) mm |

| Titanium foil / eriri | (0.01 ~ 2.0) mm × (800 ~ 1560) mm × L |

| Ọkụ Titanium / Ọkụ | Ф(3~114)mm ×( 0.2~5)mm × (~15000)mm |

| Ụkpụrụ | GB,GJB,ASTM,AMS,BS,DIN,DMS,JIS,GОСт |

| Titanium ọkwa |

|

Ngosipụta ngwaahịa